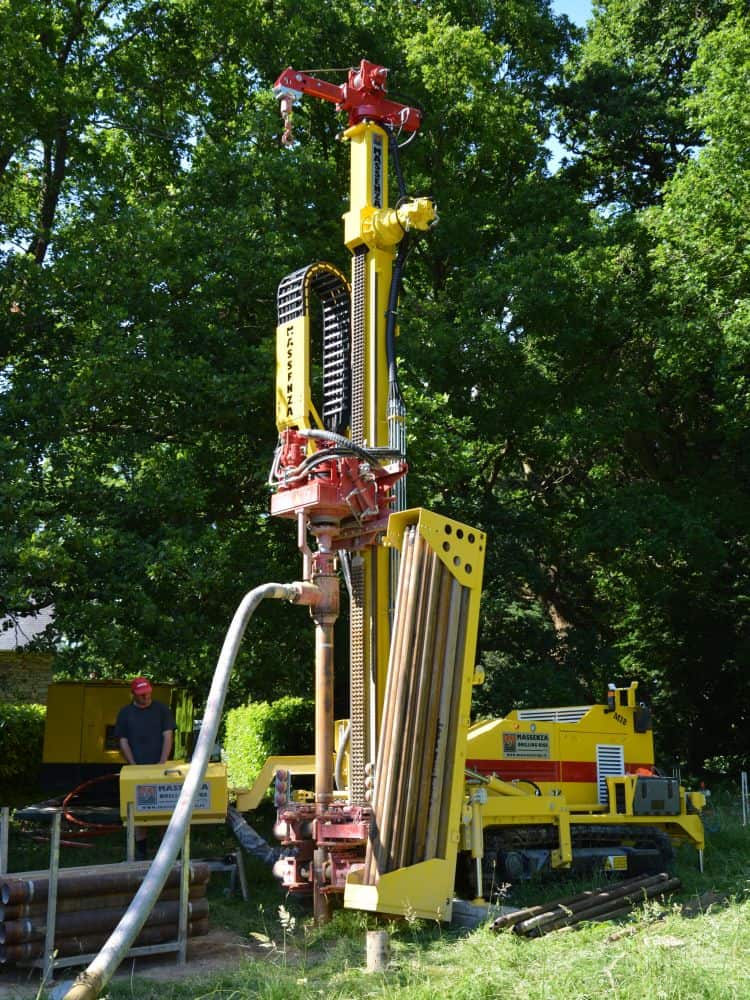

VIDEO - DRILLING RIG MI8 FOR GEOTHERMAL BOREHOLES WITH CASING DRIVE SYSTEM, NO NEED FOR EXPENSIVE AND BULKY DOUBLE ROTARY HEAD

The casing drive system, as you can see in the video, is utilized when drilling with a DTH hammer in inconsistent soil.

Under such conditions it is very likely the borehole will collapse. The solution adopted so far is to use a double rotary head: one to drive the drill pipes and one to drive the casing which are positioned simultaneously. This solution is however very expensive in terms of initial investment (two rotary heads instead of one), in terms of drilling costs (high fuel consumption) and finally in terms of maintenance (spare parts for two rotary heads, more powerful engines etc.).

As a better alternative the casing drive system needs just one rotary head for driving both the drill pipes and the casing. This system is really simple and the benefits are remarkable:

The final result is the same obtainable with the double rotary head

The rig is smaller and lighter

The initial investment costs are considerably lower

The drilling costs are considerably reduced

POWER PACK

Engine power 156 Hp (115 kW)

FUEL TANK

Capacity 150 litri (39,6 gal)

SLIDING MAST: stroke 900 mm (3 ft)

MAST: max. stroke of rotary head 4,1 m (13 ft 6)

Max pull up and down: 12.000 daN (26.977 lbf)

ROTARY HEAD

Max torque 11.000 Nm (8.115 lbfft)

Max speed 130 Rpm

WINCH

Max line pull 3.100 daN (6.970 lbf)

DOUBLE HYDRAULIC CLAMP

Model MS360: max passagge Ø 360 mm (14)

CASING EXTRACTOR:

Max pull up 25 tons (55.115 lbf)

TILTING PIPES RACK

CASING DRIVE SYSTEM

Under such conditions it is very likely the borehole will collapse. The solution adopted so far is to use a double rotary head: one to drive the drill pipes and one to drive the casing which are positioned simultaneously. This solution is however very expensive in terms of initial investment (two rotary heads instead of one), in terms of drilling costs (high fuel consumption) and finally in terms of maintenance (spare parts for two rotary heads, more powerful engines etc.).

As a better alternative the casing drive system needs just one rotary head for driving both the drill pipes and the casing. This system is really simple and the benefits are remarkable:

The final result is the same obtainable with the double rotary head

The rig is smaller and lighter

The initial investment costs are considerably lower

The drilling costs are considerably reduced

POWER PACK

Engine power 156 Hp (115 kW)

FUEL TANK

Capacity 150 litri (39,6 gal)

SLIDING MAST: stroke 900 mm (3 ft)

MAST: max. stroke of rotary head 4,1 m (13 ft 6)

Max pull up and down: 12.000 daN (26.977 lbf)

ROTARY HEAD

Max torque 11.000 Nm (8.115 lbfft)

Max speed 130 Rpm

WINCH

Max line pull 3.100 daN (6.970 lbf)

DOUBLE HYDRAULIC CLAMP

Model MS360: max passagge Ø 360 mm (14)

CASING EXTRACTOR:

Max pull up 25 tons (55.115 lbf)

TILTING PIPES RACK

CASING DRIVE SYSTEM