DIRECT CIRCULATION DRILLING

This system allows you to drill all types of terrain and reach the maximum depth that drilling technologies currently allow.

Generally used for the construction of small and medium diameter wells, this technique allows drilling without the use of temporary casing pipes.

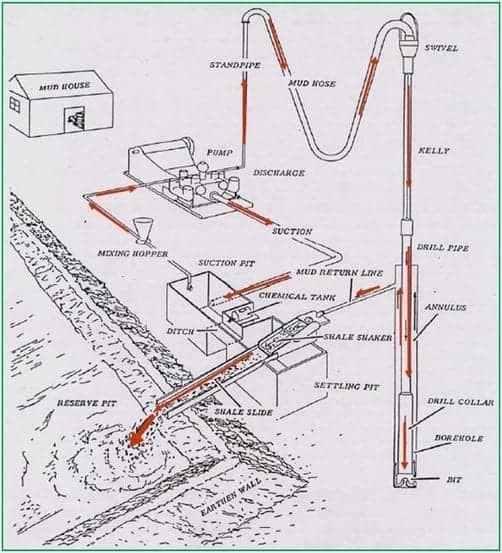

The direct circulation method occurs through the pumping of the circulating fluid (bentonite and/or polymers based mud) inside the rods. It is then returned back in the annulus between the rods and the hole, with the material drilled by the bit.

The pressure and flow of the drilling fluid at, and immediately behind, the drilling bit effectively flushes the drilled material away from the bit and also prevents the borehole from collapsing.

Further back from this the hydrostatic head of the drilling fluid ensures the stability of the hole and its viscosity (calculated according to the flow of fluid provided from the drilling rig and the diameter of the hole) must be such as to allow the transport to the surface of the drilled material.

To allow effective removal of material without exceeding in viscosity, the ascent speed of the fluid should be not less than 0.2 m/sec.

The excavation system can use the force of impact of a tool, which operates mainly by percussion/compression or by the combined action of the cutting resulting from the combination of the rotation of the tool and the torque applied to it.

The minimum pull back of the rig must be at least 30% greater than the weight of the drill string.

Optimal depth: from 0 up to 1000 m

Optimal diameter: from 152 up to 444 mm (from 6” up to 17”1/2)

SOIL

This technique can be used effectively in all types of soils, both alluvial sedimentary rocks or crystalline.

In severely fractured formations it may be necessary to use cementation or casing pipes.